How American Plastics HDPE Pipe Manufacturing Maintains High Standards

Wiki Article

Comprehending the Key Perks of HDPE Pipeline for Water and Wastewater Monitoring

Using HDPE pipe in water and wastewater administration provides countless benefits that merit consideration. Its extraordinary longevity and long life expectancy make it a recommended selection for lots of projects. Furthermore, the product's resistance to deterioration and chemical damage improves its reliability in numerous atmospheres. The advantages expand past just durability and resistance. custom hdpe pipe manufacturing Midland TX. Discovering its cost-effectiveness and ecological effect discloses much more compelling factors for its prevalent adoption in contemporary facilitiesRemarkable Sturdiness and Durability

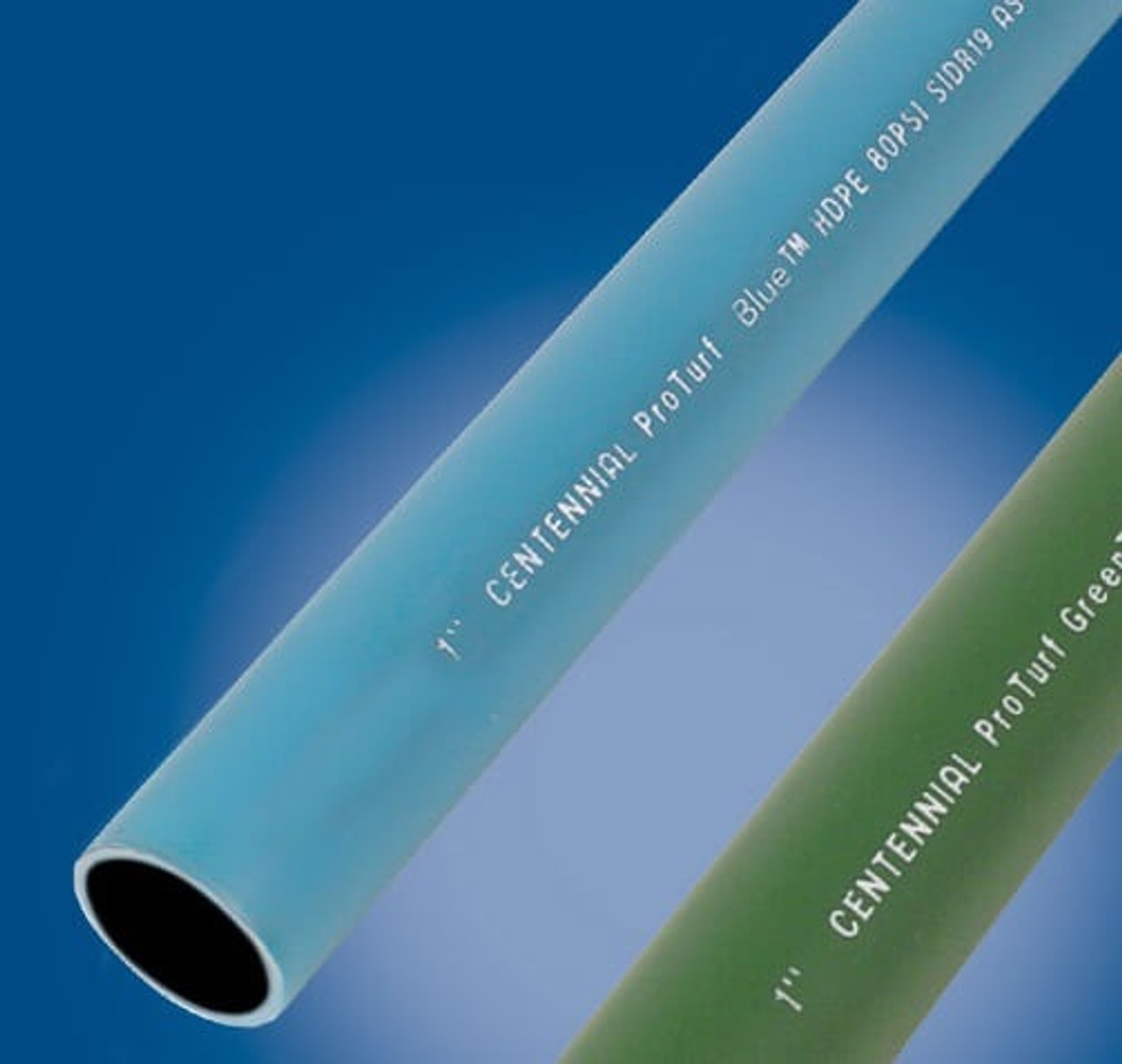

HDPE pipe stands apart for its extraordinary durability and durability, making it a recommended choice in water management systems. Created from high-density polyethylene, these pipes can stand up to significant stress and stress, ensuring reliable performance over time. Their robust nature allows them to sustain extreme environmental problems, consisting of temperature level fluctuations and dirt activities, which can create various other products to fall short.

The lifespan of HDPE pipelines commonly surpasses 50 years, supplying an affordable option for towns and industries alike. In addition, the material's light-weight buildings simplify installment, decreasing labor prices and durations. This durability decreases the requirement for regular repair services or substitutes, even more enhancing its financial appeal.

In water management applications, the reliability of HDPE pipelines indicates fewer disruptions and enhanced service connection, making them essential to lasting infrastructure advancement. The mix of toughness and longevity solidifies HDPE's function as a foundation in efficient water monitoring options.

Resistance to Corrosion and Chemical Damage

While several materials surrender to deterioration and chemical damage in time, HDPE pipes exhibit exceptional resistance, making them excellent for numerous water monitoring applications. This resilience originates from the molecular framework of high-density polyethylene, which is inherently non-reactive and does not corrode like metals or degrade from direct exposure to severe chemicals. Consequently, HDPE is extremely reliable in atmospheres with aggressive compounds, such as wastewater systems that may contain acids, bases, and natural solvents.

In addition, HDPE pipes can withstand environmental elements such as dirt acidity and saline problems, even more improving their suitability for diverse applications (Pipe Supplier American Plastics Midland). Their capacity to keep architectural stability over time decreases the danger of leaks and failures, which is essential in making certain the security and integrity of water circulation and wastewater management systems. Subsequently, the resistance to deterioration and chemical damages substantially contributes to the general efficiency and long life of HDPE piping options

Cost-Effectiveness and Economic Advantages

When taking into consideration the economic implications of water management systems, the cost-effectiveness of HDPE pipelines comes to be obvious. These pipes supply lower setup and maintenance expenses compared to standard products like metal or concrete. Their lightweight nature streamlines transportation and setup, leading to lowered labor expenditures. Furthermore, HDPE pipelines show a lengthy life expectancy, typically exceeding half a century, which converts to fewer replacements and lasting savings.The resistance of HDPE to deterioration and chemical damages decreases the need for expensive fixings and replacements. The pipelines additionally sustain reliable water flow, lowering energy costs linked with pumping systems. By minimizing leaks and water loss, HDPE pipelines add to significant economic advantages for towns and sectors alike. In general, the first investment in HDPE piping can produce significant monetary returns over the lifespan of the water administration system, making it a prudent option for sustainable framework advancement.

Environmental Sustainability and Lowered Influence

Convenience and Adaptability in Installment

As a result of their special residential or commercial properties, HDPE pipelines supply impressive flexibility and adaptability in installation, making them suitable for a wide variety of applications. Their lightweight nature allows for much easier handling and transportation, minimizing labor costs and installation time. HDPE pipes can be curved and formed to fit different terrains and job requirements, which is specifically useful in challenging atmospheres.Furthermore, their resistance to rust and chemical damage enables setup in diverse setups without the requirement for specialized safety finishings. The capacity to fuse joints creates a continual, leak-free system, enhancing the general integrity and integrity of the installment. HDPE's versatility likewise accommodates ground motion, decreasing the risk of damages in locations susceptible to moving soil. Overall, these attributes make HDPE pipelines not only versatile yet also a preferred option for water and wastewater management systems.

Often Asked Concerns

Exactly How Does HDPE Pipeline Compare to PVC in Water Management Applications?

HDPE pipeline provides remarkable adaptability, resistance to corrosion, and resilience compared to PVC. Its lighter weight promotes simpler installment, while its lengthy lifespan lowers replacement expenses, making HDPE a favored option in water management applications.What Is the Life-span of HDPE Pipes Under Normal Problems?

Under normal problems, HDPE pipes can have a life expectancy ranging from 50 to 100 years. Their longevity and resistance to rust add to their lasting performance in various applications, making them a trusted choice for infrastructure.Are HDPE Piping Recyclable After Their Life Span?

Yes, HDPE pipes are recyclable after their life span. American Plastics HDPE Pipe for Oilfield. They can be processed and repurposed into new items, significantly decreasing ecological impact and promoting sustainability within the sector, making them an eco-friendly selection for piping solutionsWhat Is the Installation Refine for HDPE Pipes?

The setup process for HDPE pipelines involves site preparation, trenching, pipe combination or mechanical signing up with, backfilling, and stress screening. Proper methods guarantee a sturdy and read more effective system for moving water and wastewater successfully.Can HDPE Pipes Be Made Use Of for Both Drinkable and Non-Potable Water Systems?

Yes, HDPE pipes can be utilized for both safe and clean and non-potable water systems. Their versatility, durability, and resistance to rust make them ideal for various applications, making certain safe and effective transportation of water in different contexts.Report this wiki page